Hi there!

Over the last few years, I've been down a deep rabbit hole with "vintage technology." To me, the experience of driving a car (which includes being driven or chasing any leak paths in it), or taking pictures looking through a piece of ground glass (and developing and enlarging film) are similar -- they're more about the journey than about the outcome. I think a lot of that has been lost in translation to our current digital age, which focuses heavily on getting the "perfect" outcome every time. You could say I've been chasing the art of imperfection, and "wasting" my time tinkering and trying out ideas. In addition to complex machines, I've worked on rebuilding a lot of simple machines with updating vintage machinery used in my woodshop.

It is also equally as fun to visit places around the world that happen to still have working technology that has long since been squirreled away. Some amazing places I've been to are the TCMIT in Nagoya (this showcases the Toyota machine development from weaving through automotive technologies and despite the language barrier there, the guides are passionate about showing you how things work, and that doesn't need much translation), and the MOTAT in Auckland (which besides having working devices you could play with, also had technicians and shops you could walk into). I travel mostly for food, but still-working machines are always fascinating to see.

My attempt at a short bio:

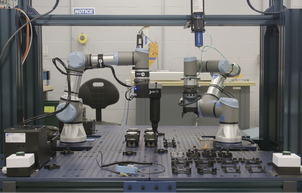

I'm from the greater Los Angeles area, and am a robotic systems engineer living on the East Coast. My current adventure is that I am the second cofounder at a company called Hellbender Inc. which is focused on developing rugged on-edge IoT sensors with in-house PCB assembly and robotics assembly. I have a Masters in Robotics Engineering at Worcester Polytechnic Institute and graduated with an Engineering degree with a concentration in Robotics (E: Robo) at Olin College of Engineering. My previous lives involve testing lots of robots ranging from magnetic ship crawlers to driverless cars, as well as leading the hardware test and production design development for an autonomous commercial floor scrubber.

I luckily have a very supportive significant other (who conveniently was an auto technician and is a professional electromechanical (robotics) engineer) who gets to listen to my ideas and often works on these projects with me. It's always felt like I've got too many ideas and not enough time. The upside is that we both generally want more tools (and that's how we've ended up with woodshop 2.0 and a garage car workshop). The downside is neither one of us is very good at stopping the other from getting something we think we'll need or use often. (But all the tools!)

It is also equally as fun to visit places around the world that happen to still have working technology that has long since been squirreled away. Some amazing places I've been to are the TCMIT in Nagoya (this showcases the Toyota machine development from weaving through automotive technologies and despite the language barrier there, the guides are passionate about showing you how things work, and that doesn't need much translation), and the MOTAT in Auckland (which besides having working devices you could play with, also had technicians and shops you could walk into). I travel mostly for food, but still-working machines are always fascinating to see.

My attempt at a short bio:

I'm from the greater Los Angeles area, and am a robotic systems engineer living on the East Coast. My current adventure is that I am the second cofounder at a company called Hellbender Inc. which is focused on developing rugged on-edge IoT sensors with in-house PCB assembly and robotics assembly. I have a Masters in Robotics Engineering at Worcester Polytechnic Institute and graduated with an Engineering degree with a concentration in Robotics (E: Robo) at Olin College of Engineering. My previous lives involve testing lots of robots ranging from magnetic ship crawlers to driverless cars, as well as leading the hardware test and production design development for an autonomous commercial floor scrubber.

I luckily have a very supportive significant other (who conveniently was an auto technician and is a professional electromechanical (robotics) engineer) who gets to listen to my ideas and often works on these projects with me. It's always felt like I've got too many ideas and not enough time. The upside is that we both generally want more tools (and that's how we've ended up with woodshop 2.0 and a garage car workshop). The downside is neither one of us is very good at stopping the other from getting something we think we'll need or use often. (But all the tools!)

If it is of interest, here are some links to my old sites.

A Wee Portfolio (professional, mostly college era things)

Wee Atlas v1 (older travel blog about trips to Asia)

Wee Atlas v2 (more recent travel blog)

(My general verdict is that blogging is overrated and the available templates are sub-par at best. So I've decided to consolidate most of it here.)

A Wee Portfolio (professional, mostly college era things)

Wee Atlas v1 (older travel blog about trips to Asia)

Wee Atlas v2 (more recent travel blog)

(My general verdict is that blogging is overrated and the available templates are sub-par at best. So I've decided to consolidate most of it here.)